AT2

About Us

We uphold our mission and philosophy

Fang Cheng constantly pursues

innovation

、

peace of mind

、

professionalism

and

a sense of responsibility towards our customers

Fang Cheng insists on implementing the standards of food hygiene inspections. The production and manufacturing processes are both carried out with the “highest performance” and the “most professional service attitude”. In 2022, we introduced environmentally friendly electronic inks, which comply with the dual certifications of FDA and EUPIA for food packaging printing. We strive to create “safe”, “reassuring”, “convenient” and “diverse” food-contact packaging for our customers.

Fang Cheng insists on implementing the standards of food hygiene inspections. The production and manufacturing processes are both carried out with the “highest performance” and the “most professional service attitude”. In 2022, we introduced environmentally friendly electronic inks, which comply with the dual certifications of FDA and EUPIA for food packaging printing. We strive to create “safe”, “reassuring”, “convenient” and “diverse” food-contact packaging for our customers

AT2

Factory Environment

AT2

Historical Development

Fang Cheng Co., Ltd. was formerly known as Hong Ji Xing, which was established in January 2002 in the simple and honest township of Dapi in Yunlin County. We produced packaging materials for agricultural use and designed and developed packaging materials for Phalaenopsis orchids for export to Japan. We hold multiple patents both domestically and internationally, and have also developed specialized bags for butterfly orchids.

We moved into a new factory in Dou Nan Town in April, with an area of 1200 square meters. We also developed an export-oriented water storage rack for Platycodon grandiflorus and applied for a patent for it. We established our own brand, AT2, with a focus on technology, agriculture, and environmental protection as our main appeals, to establish a confident market image.

In August, with the support of our official channel partners, we enhanced our existing processing technology to make our products more distinctive and of higher quality. We also began producing packaging materials for 3C products such as LCD screens, laptops, and tablets.

In November, Fong Cheng Co., Ltd. was officially established, and multiple new products were developed. Our business expanded to the field of industrial protective clothing and OEM bedding for dust mite protection.

In October, the company expanded again by purchasing the 3700-ping Tu-ku II factory, and was planning to introduce ISO 9001:2008 in 2013 to make the company's products meet international standards in terms of production process, quality, and internal management.

Translation: In March, our company officially passed the ISO 9001:2008 quality management system verification.

In August, in response to the domestic food safety issues and the upgrading of packaging materials, our company entered the field of food packaging materials. In order to provide customers with safer and better products, we introduced new machinery and followed the ISO 22000 food safety and hygiene management system, incorporating the principles of HACCP and the spirit of GHP (Good Hygiene Practice for Food). We also strengthened the control of environmental food packaging materials, the hardware construction of the factory, and the training of personnel to achieve perfection. Currently, our company is actively cultivating a food safety team and providing education and training for employees, as well as renovating the factory. It is expected that we will pass the ISO 22000 food safety management system verification by the end of this year or early next year.

In March, our company officially passed the ISO22000 and HACCP food safety management system verification.

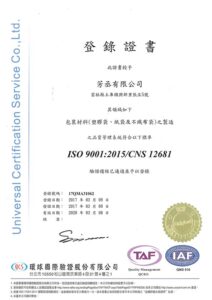

Sustainable management in March is our unchanged goal. With the advancement of the concept of quality in the era, we have completed the transition from the old version of quality management (ISO 9001:2008) to sustainable quality (ISO 9001:2015).

The key points of this transition include:

1.Enhancing the applicability of service quality improvement.

2.Emphasizing the internal and external environment of the company.

3.Increasing the requirements for the senior leadership level.

4.Introducing the concept of risk and strengthening the system's response measures.

5.Reducing the required regulatory requirements and relaxing the requirements for formal documentation.

6.Enhancing the specific requirements for performance evaluation.

In January, our company obtained a license for pharmaceutical sales business.

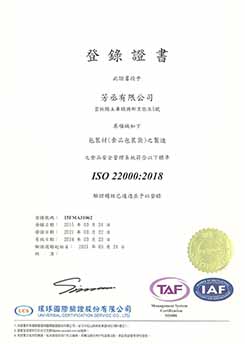

The importance of food safety awareness has been increasing in March. In order to enhance our self-requirements for the international food safety management system, we have completed the transition from the old version (ISO 22000:2005) to the new version (ISO 22000:2018).

The key points of this transition include:

1.Planning hardware that meets official requirements.

2.Enhancing customer trust in the company and its products.

3.Reducing costs associated with errors.

4.Managing resources related to food-related documentation.

5.Strengthening systematic and planned monitoring, reducing the cost of post-process inspection.

6.Optimizing the operation of the organization and improving efficiency and effectiveness."

In June, our company obtained a manufacturing license for medical equipment and officially passed the verification of the ISO 13485:2016 quality management system.

In October, our company obtained the first-class medical equipment license from the Ministry of Health and Welfare.

AT2

Mechanical Processes

We have a variety of equipment to create an integrated production line service.

To fulfill customer demands

Customized size

and

OEM manufacturing.

AT2

Testing Equipment

Fang Cheng has professional testing equipment to perform the highest standard tests on products' maximum load capacity.

Fang Cheng has professional testing equipment to perform the highest standard tests on products' maximum load capacity.

Ensure that the products delivered to customers are of the highest quality.

AT2

Professional Certification